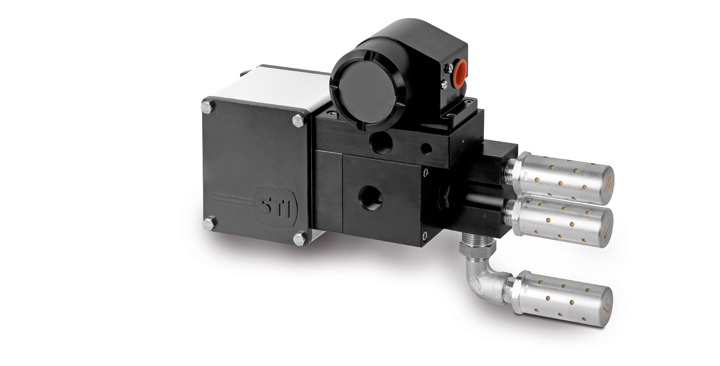

SA/CL & SA/CL-EP

The SA/CL positioner is formed by:

• a diaphragm on which the pneumatic control signal operates;

• a feed-back spring;

• a double acting spool valve connected to the diaphragm by rod.

Control pressure, operating on diaphragm, opposes to the spring, causing spool valve to displace and, consequently, the cylinder stem to be actuated.

The stem displacement is transmitted to the feed-back spring through cam and lever.

Therefore the actuator stem is a stable position only when the feed-back spring balances exactly the force generated by the pneumatic signal on the diaphragm and spool valve is in a neutral position.

- Air supply: 1/4" NPTF (1/2" NPTF for positioner SA/CL1-2)

- Dry instrument air: max. 665 kPa (100 psig)

- Input signal: 4 to 20 mA / 3 to 15 psi (special ranges on request)

- Linearity: 1% of the stroke (direct action)

- Outputs: 1/4" NPTF (1/2" NPTF for positioner SA/CL1-2)

- Operating temperature: -20°C to + 80°C (lower and higher temperatures available on request)

- Sensitivity: 0,25% of signal range

- Signal pressure gauge: 1/8" NPTF

- Standard cam: linear (quadratic or other shapes available on request)

- Static consumption: 1,02 Nm^3/h (0,6 SCFM) at 400 kPa (60 psi)

(Technical information refers to SA/CL1 positioner ND 1/4" coupled to STI actuators)